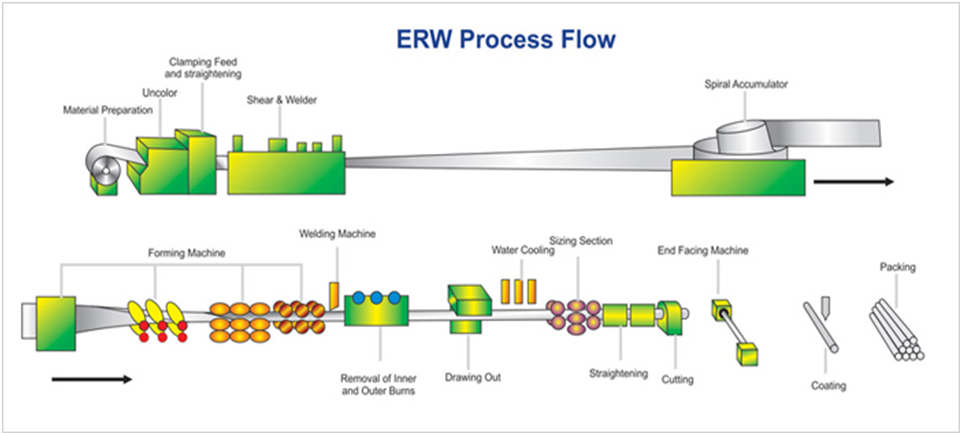

The basic raw material for manufacturing of pipes is HR / CR / GP Coils. After receiving the raw material in Coil shape these are slitted into various widths according to requirements of Pipe Dia at Slitting machine.

After slitting the slitted coil is loaded on the un coiler and stored in accumulator to enable the continuous running of the mill while tail end of slit is welded with the leading end of next coil with the help of MIG welding. The strip is passed through a set of rolls to get the shape and the outer edges of strip are heated by high frequency induction coil. Outside flash of welding is removed with the help of round tool (Scarfing tool) so as to give better finish. The welded tube is again passed through a set of rolls to get the specified tolerances on outside Diameter. Inside flash of weld can also be removed if required by the customer above 75mm outside Diameter. Our product Range is from 25.40mm OD to 114.03mm OD . After the pipes are made these are cut into the Required lengths in COLD SAW.